Understanding Epoxy Resin Types and Applications

Our product range includes various epoxy resin types optimized for different application requirements. Selecting the right resin is just as critical to the success of your project as choosing the correct hardener. Below is an overview of the primary resin technologies we provide:

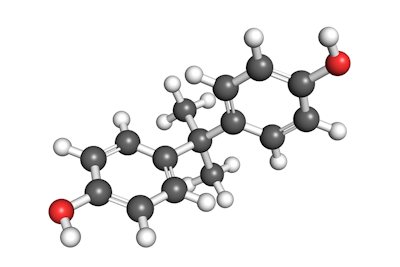

- Standard Liquid Epoxy Resins (DGEBA): The industry standard for multi-purpose applications. These resins provide high mechanical strength and are the backbone of everything from industrial floor coatings to structural adhesives.

- Low Viscosity & Casting Resins: Specifically engineered for deep-pour projects like river tables and detailed hobby crafts. Their thin consistency facilitates easy air bubble release and ensures crystal-clear transparency.

- Novolac Epoxy Resins: Designed for high-performance industrial environments that demand extreme chemical resistance and thermal stability. They are the go-to solution for acid storage tanks and specialized anti-corrosion linings.

- Water-Based Epoxy Resins: An eco-friendly, low-odor alternative for projects requiring breathable coatings. These are ideal for indoor flooring and areas where solvent emissions must be minimized.

Reactive Diluents: Optimizing Processability

To further customize the handling and performance of epoxy systems, we offer high-purity reactive diluents. Unlike standard solvents, these molecules react into the epoxy matrix, ensuring that the final material maintains its structural integrity without shrinkage or off-gassing.

- C12-C14 Alkyl Glycidyl Ether (AGE): This is the most widely used mono-functional reactive diluent. It is excellent for reducing the viscosity of liquid resins without significantly impacting mechanical properties. It offers superior wetting capabilities and improves the flexibility of the cured system. It is ideal for floor coatings and general-purpose adhesives.

- Ortho-Cresyl Glycidyl Ether (o-CGE): A specialized aromatic reactive diluent that provides a balanced combination of high thinning efficiency and excellent chemical resistance. It is particularly effective in maintaining the acid and solvent resistance of the system, making it a preferred choice for industrial coatings and tooling resins.

The final performance of any epoxy system is determined by the synergy between the resin, the reactive diluent, and the curing agent (hardener).

Technical Support & Samples

We are committed to the success of your projects. We provide technical formulation support to help you achieve the ideal balance of properties for your specific application. Samples of our resins, hardeners, and diluents are available upon request. Please contact us for more information or to discuss your technical requirements with our team.